Rolling filter conveyor|Bunri is a specialized manufacturer of equipment that separates and discharges sludge and chips from grinding and cutting

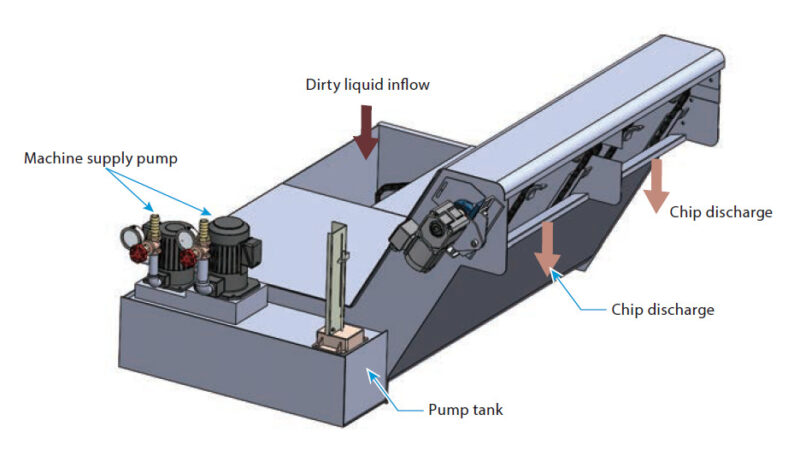

Rolling filter conveyor SAL

Double-conveyor-type punching filter conveyor.

Reduces the tank cleaning frequency.

Optimum for cutting chip processing of non-magnetic materials.

Features

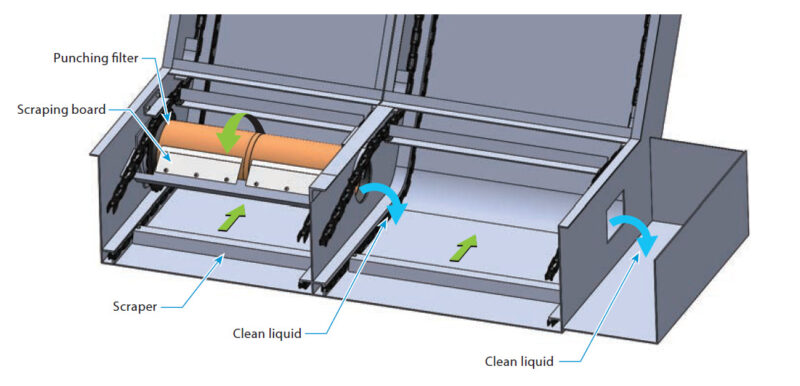

- Conveyor in which the punching filter conveyor and the scraper conveyor are arranged in parallel.

- Both conveyors can be operated with a single geared motor.

- Chips are captured in the punching filter as the primary filtration.

- The punching filter is always in contact with the scraping board and rotates to prevent clogging.

- No backwashing is required, so no mist is generated, which helps improve the environment in the factory.

- Fine chips that have passed through the punching filter accumulate in the scraper conveyor section used to collect sludge.

- The chip discharge port of the conveyor has a structure that drains liquid, which ensures that chips are drained before being discharged.This processing reduces the load to carry out coolant (means that coolant is discharged together with chips).

- This product does not use any consumables such as cartridge filters or paper filters, so no industrial waste is generated.

| Coolant | Water soluble Oil-based |

|---|---|

| Category | Non-magnetic material |

| Processing details | Cutting |

| Work material | Aluminum Stainless Copper Titanium Magnesium Mixed chips (aluminum + FC or sintered metal) |

| Chip shape | Granular Small curl-shaped (50 mm or less) Small curl-shaped (51 mm to 100 mm) |

| Grinding chip size | |

| Machine tool | Machining center Gun drill machine Cutting specialized machine |

Mechanism

- The dirty liquid flows into the punching filter conveyor (AL).

- Chips captured in the punching filter are scraped off by the scraping board and settle on the bottom of the conveyor.Then, they are discharged by the scraper.

- The clean liquid that is primarily filtered by the punching filter conveyor flows into the scraper conveyor.

- Fine chips that have passed through the punching filter conveyor settle on the bottom of the conveyor, and are discharged to the outside of the main body.

- The clean liquid that is secondarily filtered by the scraper filter conveyor is sent to the pump tank, and supplied to the machine.

- Chips are temporarily stored in the conveyor outlet, drained, and then discharged.

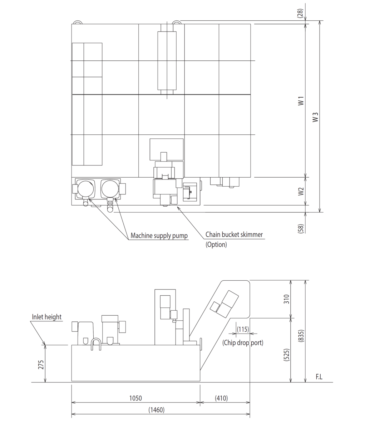

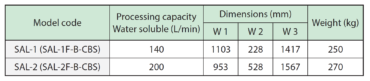

Specifications

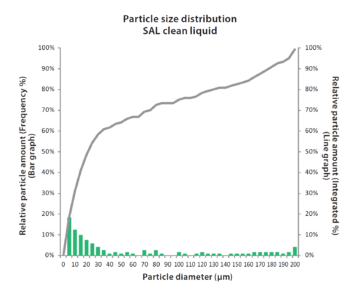

Filtration accuracy

200μm 90% or more

* The filtration accuracy is based on the results of our experiments, and does not imply that this level of accuracy is guaranteed.

Sludge distribution status

Machine tool: Machining center

Coolant: Water soluble

Processing flow rate: 700 L/min

Chip material: Aluminum

Processing flow rate

Water soluble

- SAL-1 140L/min

- SAL-2 200L/min

Product weight

- SAL-1(SAL-1F-B-CBS) 250kg

- SAL-2(SAL-2F-B-CBS) 270kg

* The product weight varies depending on the specifications, options, etc.

Paint color

Silver gray (Munsell No. N-8.0)

* For information about the specified color, please consult us.

Geared motor

40W

Chip discharge image

* Photos are product images for illustration purposes only. Specifications differ from the actual product.

* The filtration accuracy is based on the results of our experiments, and does not imply that this level of accuracy is guaranteed.

* The specifications and dimensions are subject to change without notice.

* For the oil-based specifications, please consult us.

* For information about custom products other than standard products, please consult us.

Catalog-Download

You can download a comprehensive catalog that covers Bunri's products.