Magnetic belt conveyor|Bunri is a specialized manufacturer of equipment that separates and discharges sludge and chips from grinding and cutting

Magnetic belt conveyor MB

Conveyor that conveys the tangled chips of magnetic material using the belt while adsorbing them with the magnet.

Optimum for processing tangled dumpling-shaped or curl-shaped chips.

Features

- Conveyor of which the internal magnet captures magnetic chips via the belt.

- Suitable for curl-shaped or dumpling-shaped magnetic chips that are easily entangled.

- The driven/transfer magnetic drum and mechanical screw firmly discharge chips that have entered the bottom of the conveyor or the back of the belt.

- A lineup of belt types is provided to suit chip conditions.

- This product does not use any consumables such as cartridge filters or paper filters, so no industrial waste is generated.

| Coolant | Water soluble Oil-based |

|---|---|

| Category | Magnetic material |

| Processing details | Cutting |

| Work material | FC/FCD Steel |

| Chip shape | Long curl-shaped (101 mm or more) Dumpling-shaped |

| Grinding chip size | |

| Machine tool | Machining center NC lathes Automation machine Cutting specialized machine |

Product introduction video

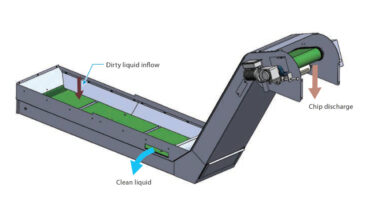

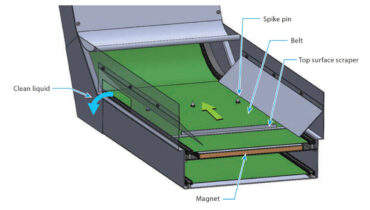

Mechanism

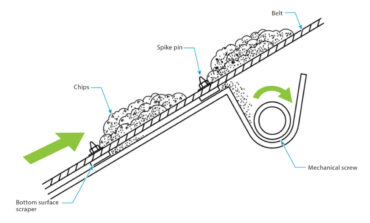

- The dirty liquid flows onto the conveyor.

- The internal magnet adsorbs the chips on the belt and conveys the chips using the assistance of the scraper.Curl-shaped and dumpling-shaped chips are also hooked using spike pins and conveyed.

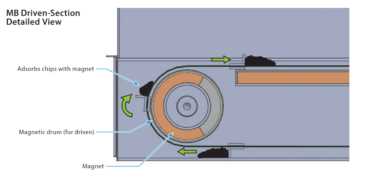

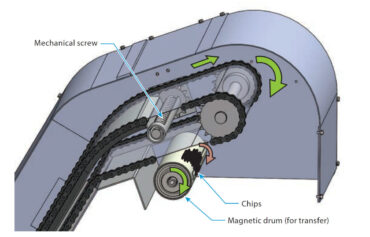

- Chips that have accumulated on the bottom of the conveyor are conveyed to the conveyor driven section (rear side) by the return scraper, and adsorbed by the magnetic drum (driven section), then conveyed onto the belt.

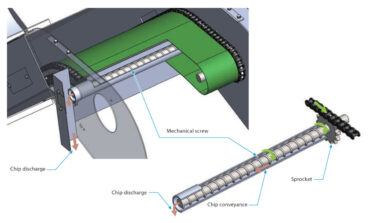

- Chips that have entered between the belt and the magnet are conveyed by the scraper on the back side of the belt and discharged to the outside of the main body by the mechanical screw attached to the top of the conveyor.

- Chips remaining on some belt surfaces are adsorbed on the magnetic drum (for transfer) and forcibly discharged to prevent chips from getting caught.

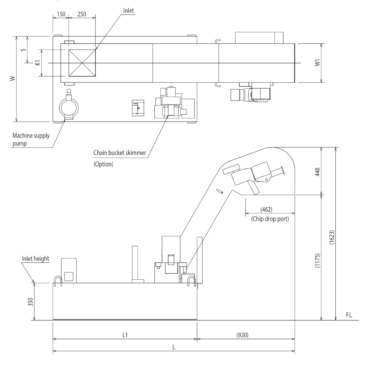

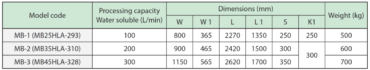

Specifications

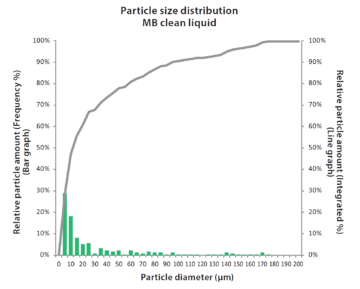

Filtration accuracy

100μm 90% or more

* The filtration accuracy is based on the results of our experiments, and does not imply that this level of accuracy is guaranteed.

Sludge distribution status

Machine tool: Machining center

Coolant: Oil-based

Processing flow rate: 250 L/min

Chip material: SUS440 (magnetic)

Processing flow rate

Water soluble

- MB-1(MB25HLA-293) 100L/min

- MB-2(MB35HLA-310) 200L/min

- MB-3(MB45HLA-328) 300L/min

Product weight

- MB-1(MB25HLA-293) 500kg

- MB-2(MB35HLA-310) 600kg

- MB-3(MB45HLA-328) 700kg

* The product weight varies depending on the specifications, options, etc.

Paint color

Silver gray (Munsell No. N-8.0)

* For information about the specified color, please consult us.

Geared motor

100W

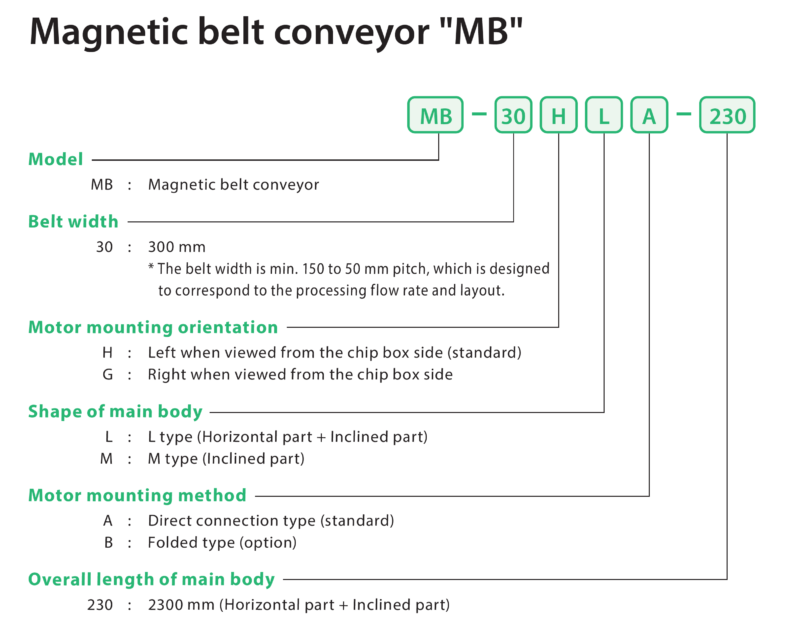

Model code

Chip discharge image

* Photos are product images for illustration purposes only. Specifications differ from the actual product.

* The filtration accuracy is based on the results of our experiments, and does not imply that this level of accuracy is guaranteed.

* The specifications and dimensions are subject to change without notice.

* For the oil-based specifications, please consult us.

* For information about custom products other than standard products, please consult us.

Catalog-Download

You can download a comprehensive catalog that covers Bunri's products.